The production of disposable paper cups involves multiple stages, each utilizing specific machinery and addressing unique technical challenges to ensure the quality and safety of the final product. Here is a detailed breakdown of the process, highlighting the machines used and the technical difficulties encountered at each stage.

Stage 1: Raw Material Preparation and Pretreatment

- Raw Material Selection: Food-grade paper is chosen as the primary material, adhering to hygiene standards.

- PE Coating: A coating machine applies a layer of PE (polyethylene) film to the paper, enhancing its strength and waterproofness. The challenge lies in achieving a uniform and thin coating without compromising the feel of the paper cup.

Stage 2: Cup Forming

- Cutting: A cutting machine precisely trims the coated paper into rectangular sheets and rolls for cup formation. Accuracy is crucial to ensure proper cup shaping.

- Forming: A cup-forming machine automatically shapes the paper into cups. The machine's design must be such that it produces cups with consistent shapes and volumes, without deformation or breakage.

Stage 3: Printing and Decoration

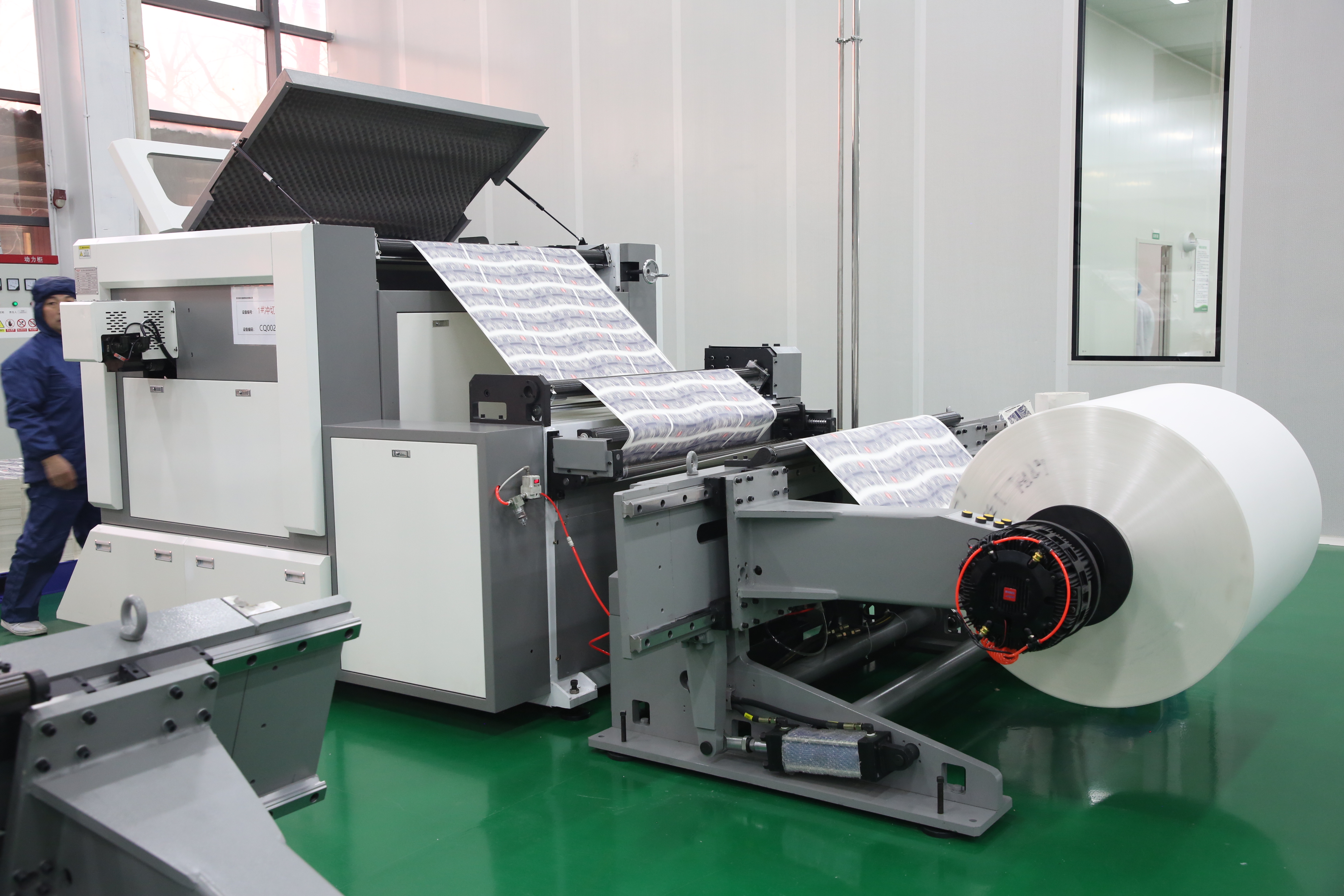

- Printing: Offset or flexographic printing machines are used to print patterns, texts, and logos on the cups. The challenge is to achieve vibrant and clear prints while ensuring ink safety and hygiene.

Stage 4: Coating and Heat Sealing

- Coating: Additional coating is applied to the interior and exterior of the cup to further enhance waterproofness. Balancing the coating thickness and uniformity is critical.

- Heat Sealing: A heat sealing machine seals the bottom of the cup. The process requires precise temperature and pressure control to ensure a leak-free seal.

Stage 5: Quality Inspection and Packaging

- Quality Inspection: Strict quality checks are conducted, evaluating dimensions, appearance, load-bearing capacity, and leak resistance. Specialized inspection equipment ensures compliance with standards.

- Packaging: Qualified cups are packed in plastic bags or cartons for safe transportation and storage. The challenge is to achieve cost-effective and environmentally friendly packaging.

Stage 6: Warehousing and Shipment

The packaged cups are stored in a warehouse, where final checks on quantity and quality are conducted. Accurate data management ensures smooth delivery to customers.

In summary, the production of disposable paper cups is a complex process involving sophisticated machinery and addressing various technical challenges. With ongoing technological advancements and process optimization, the efficiency, safety, and environmental friendliness of this production process are continuously improving.

In our pursuit of meeting the dynamic demands of our clientele, we persistently invest in cutting-edge research, development, and technological advancement. With state-of-the-art production facilities and a stringent quality control framework, we assure unwavering product quality by meticulously overseeing every facet of the process, from raw material sourcing to manufacturing.

Reach out to us today to explore packaging alternatives that not only craft unforgettable customer experiences but also contribute positively to our planet. Opt for GFP's sustainable packaging solutions and empower your choices to make a difference. Connect with us now to delve deeper into our array of eco-friendly packaging options!

Post time: Apr-26-2024